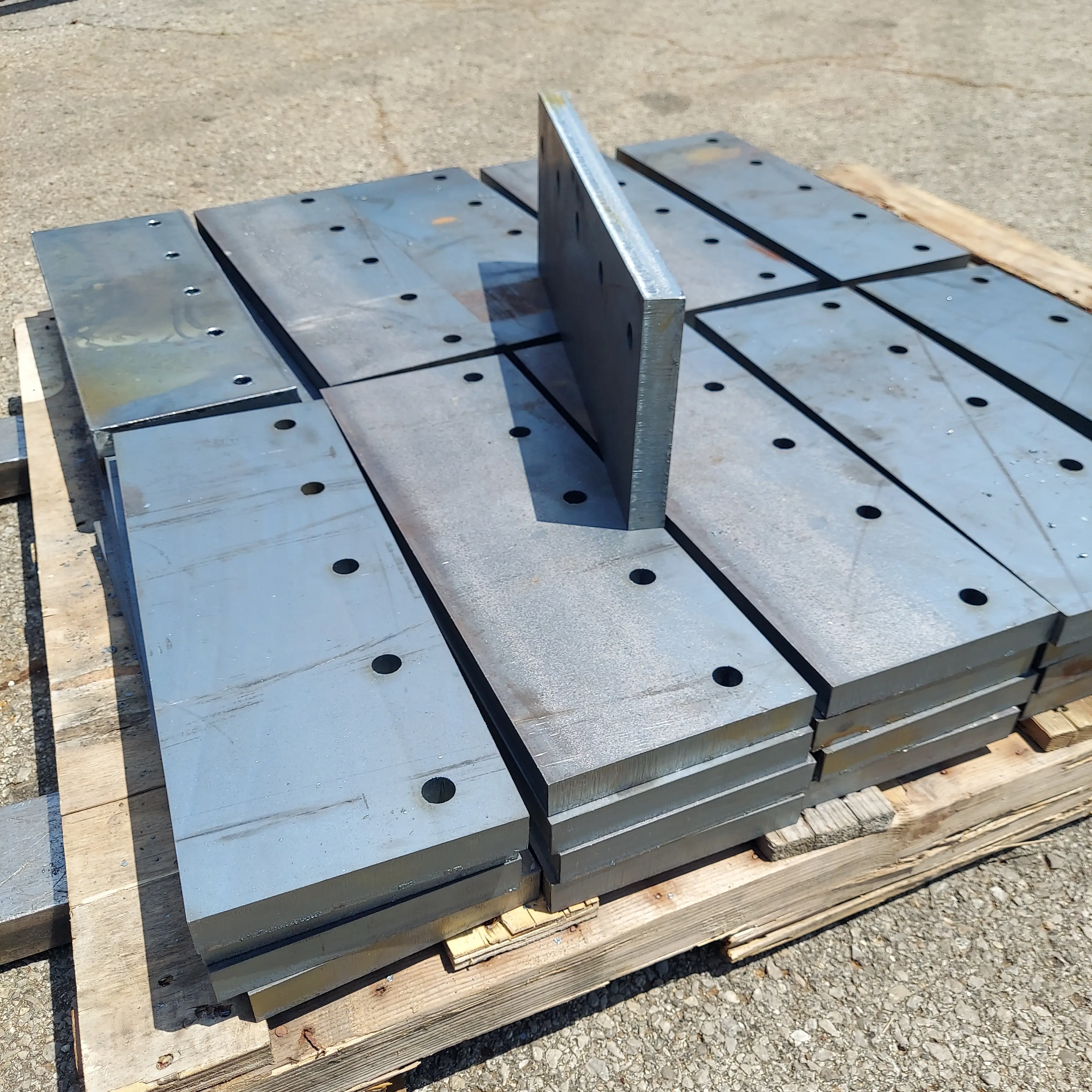

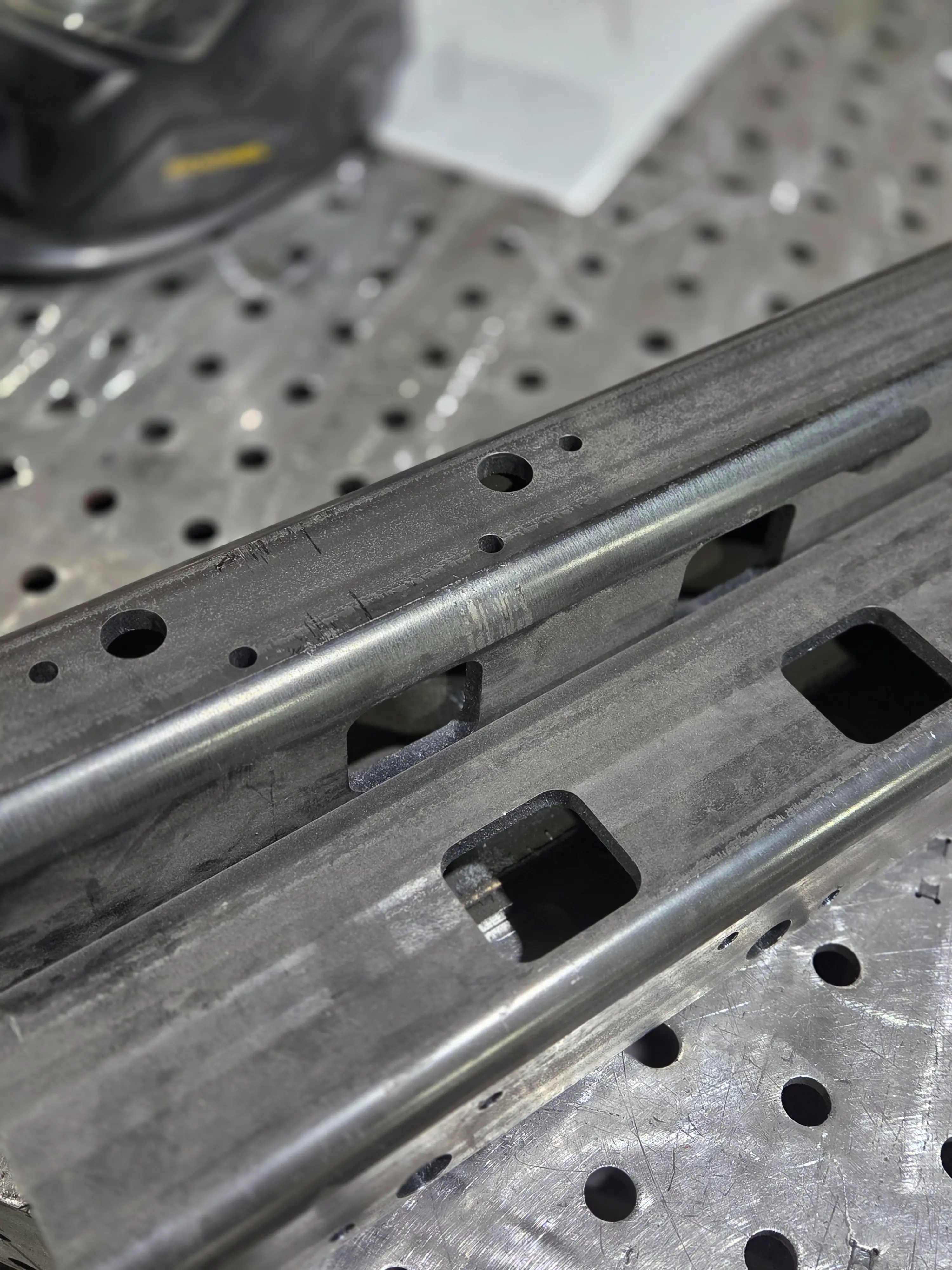

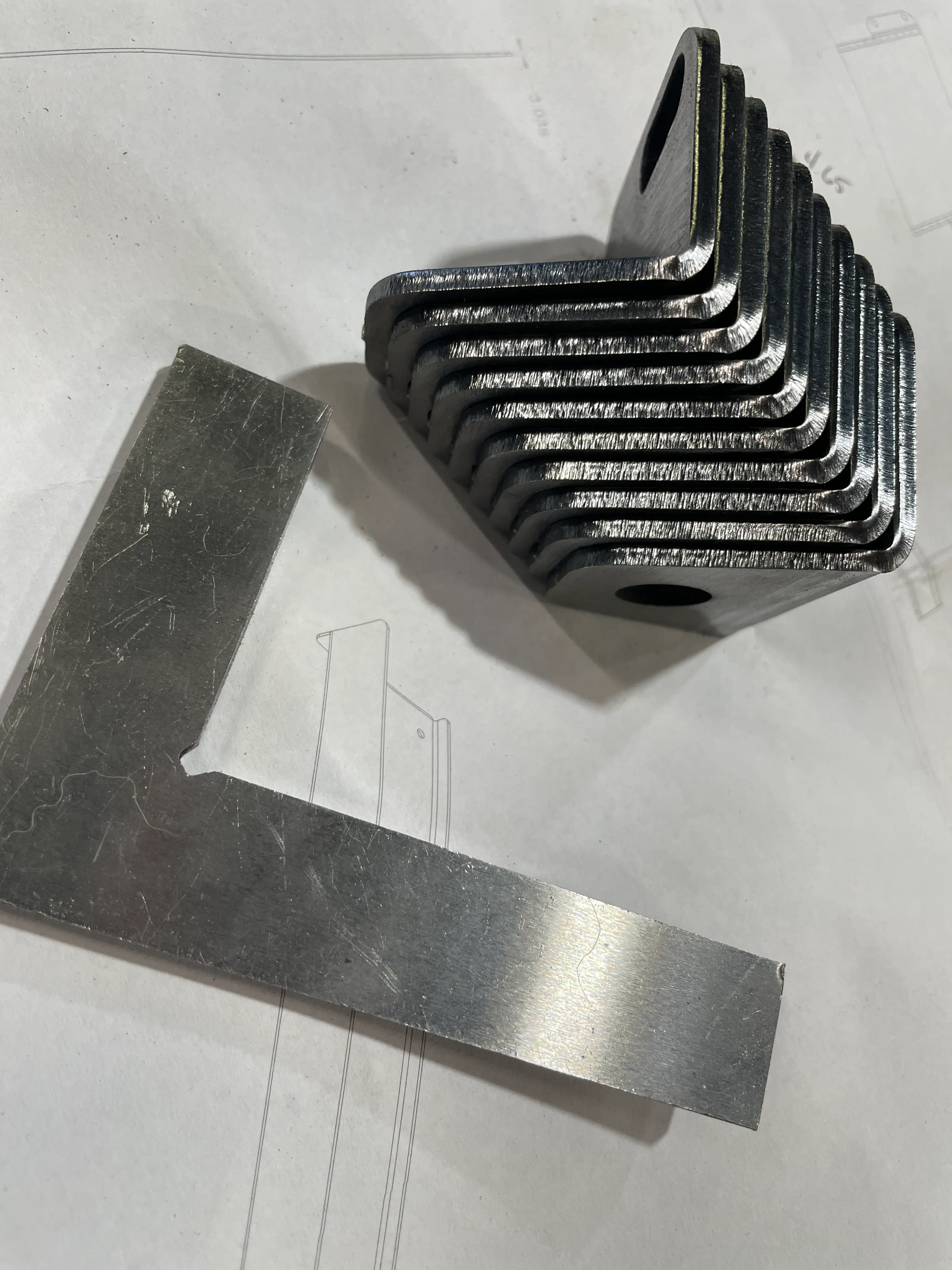

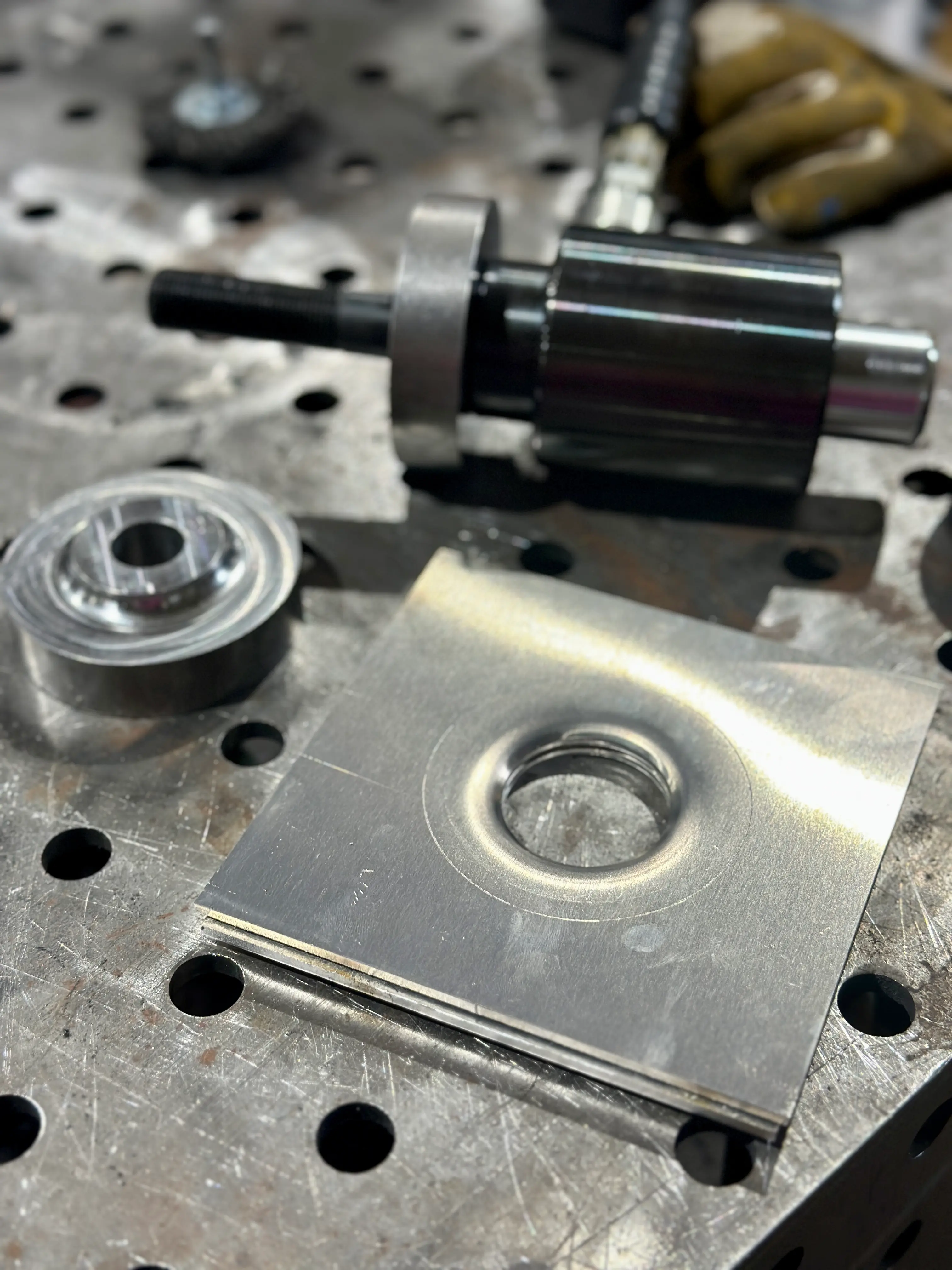

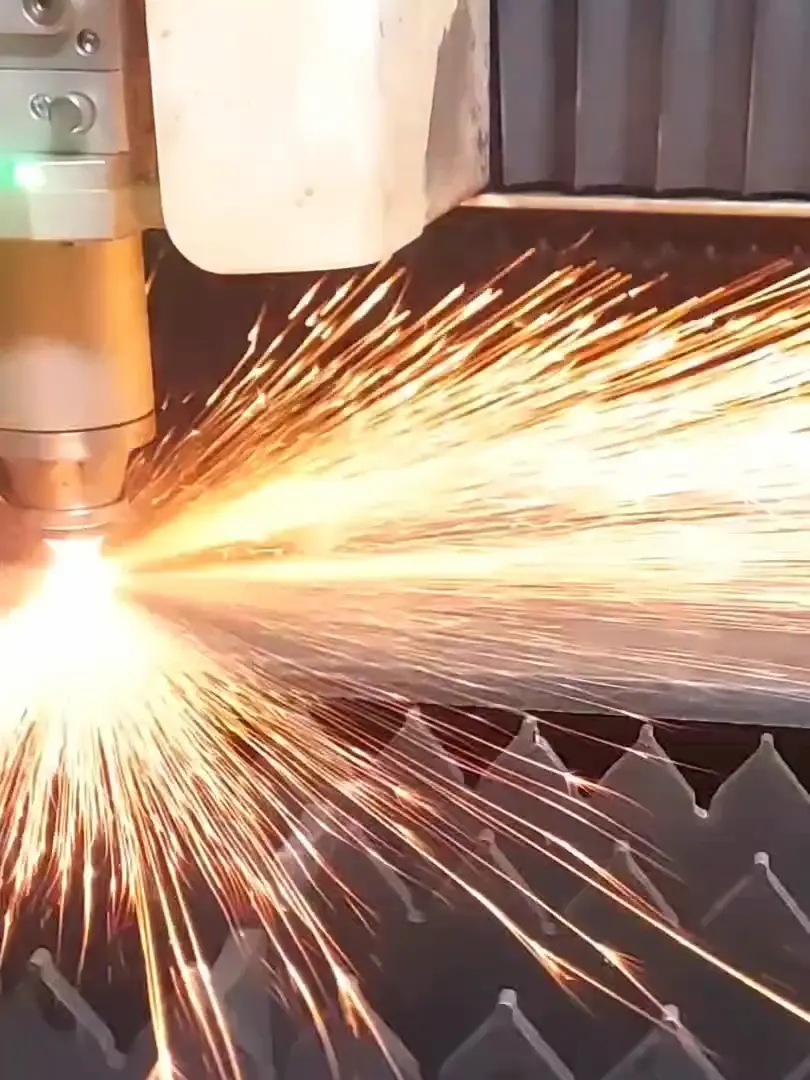

Laser Cutting &

Metal Fabrication

Industrial laser cutting, forming, and fabrication for automotive, automation, and conveyance manufacturers. From prototype to production, delivered on time.

, Inc..webp)