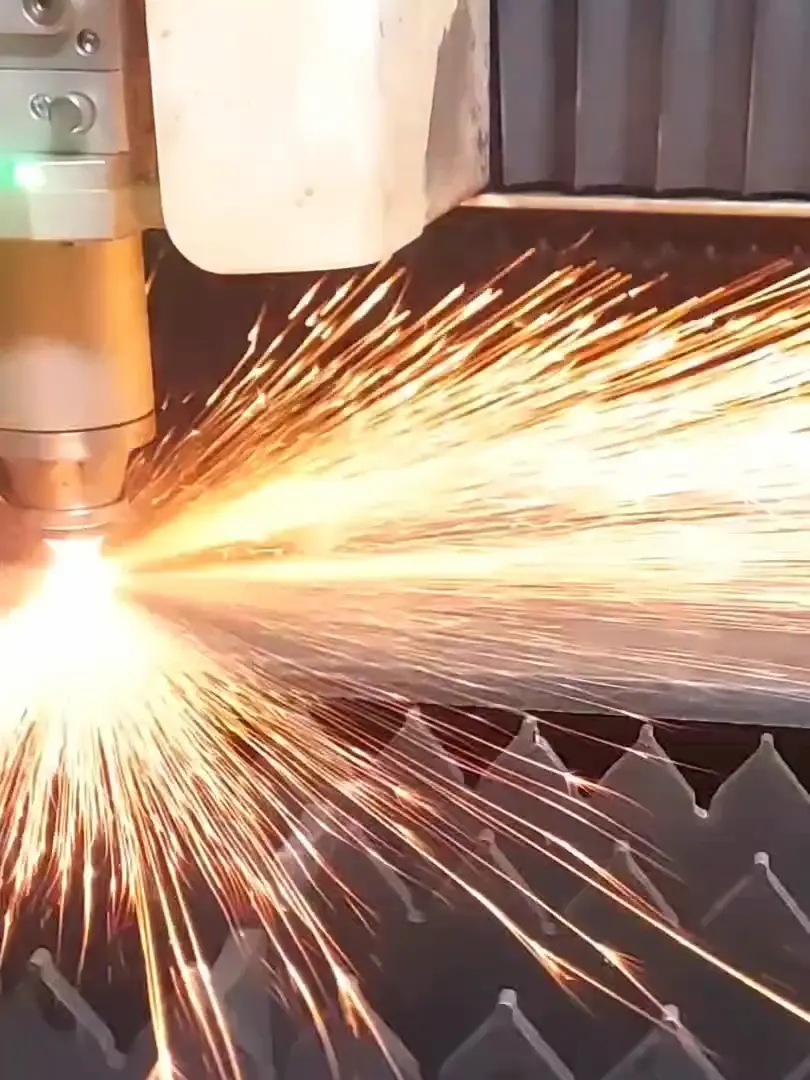

Precision Fiber

Laser Cutting

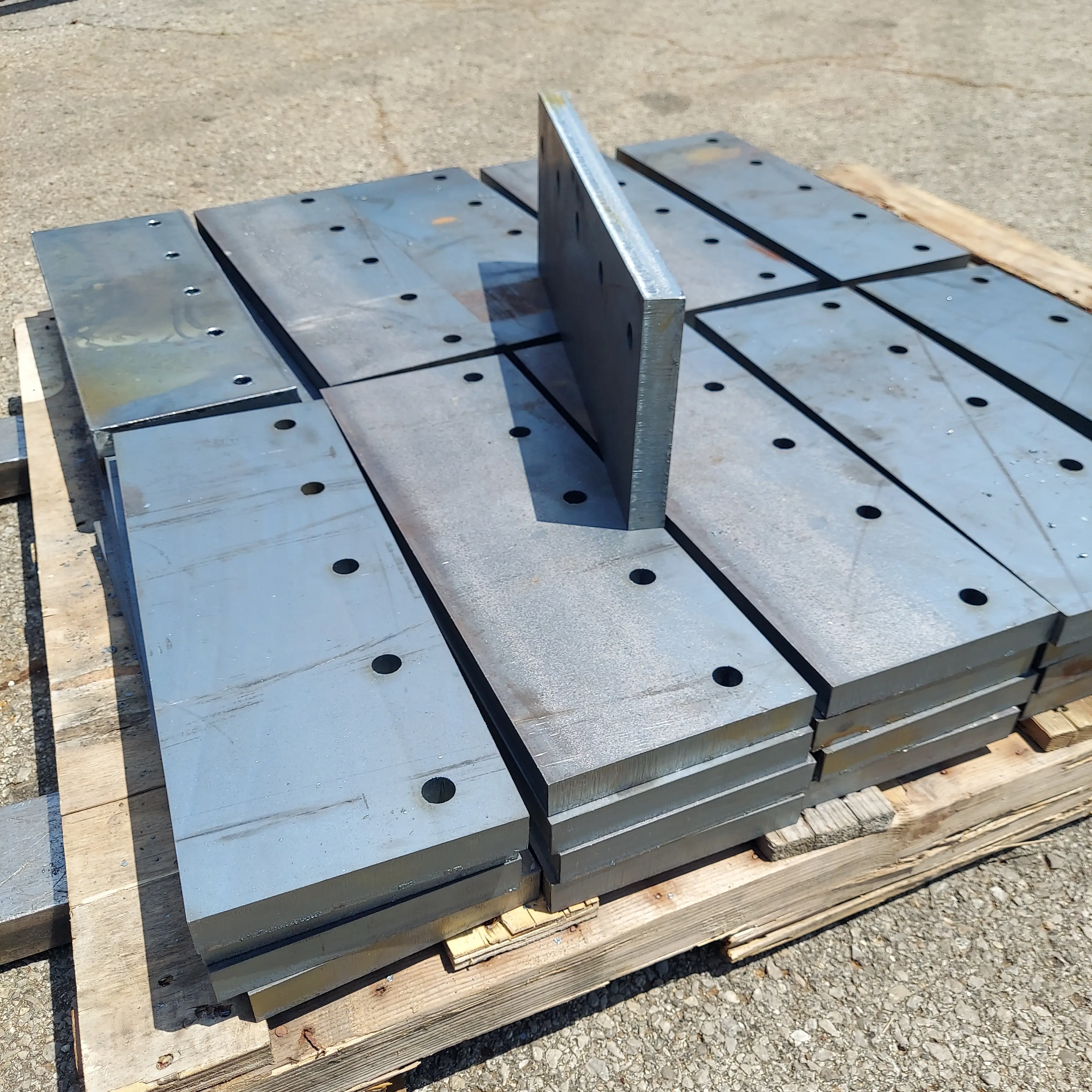

Industrial laser cutting for manufacturers who need precision parts, tight tolerances, and reliable delivery. Our 12kW fiber laser runs carbon steel, stainless, and aluminum from prototype through production.